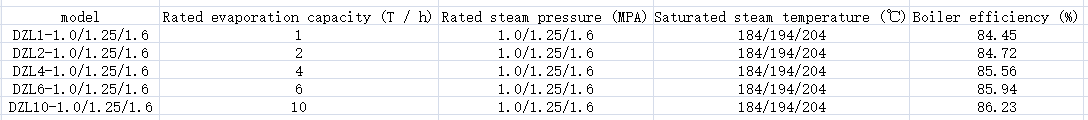

Evaporation capacity of biomass boiler: 1-10 T / h, thermal efficiency: ≥ 84%.

call the hotline to learn more

.png) +86-18103825939

+86-18103825939

.png) +86-18103825939

+86-18103825939

Evaporation capacity of biomass boiler: 1-10 T / h, thermal efficiency: ≥ 84%.

The main features of biomass boiler are as follows

1. The drum is composed of arched tube sheet and threaded smoke pipe, which makes the drum from quasi steel body to quasi single body structure, cancels the brace in tube sheet area and reduces the stress.

2. Due to the arrangement of rising pipe row at the lower part of the drum, the dead water area at the bottom of the drum is eliminated, so that the mud Bay is not easy to deposit, the high temperature area of the drum can be well cooled, and the bulging at the lower part of the boiler shell is prevented.

3.The furnace is equipped with smoke separation wall and flower wall to extend the flue gas flow, enhance the wetting disturbance of combustible gas and air, improve the fullness of flue gas in the furnace, and improve the boiler efficiency;The dust particles in the flue gas are separated and settled on the grate surface under the action of centrifugal force, and finally separated again through the flower wall dust.

4.High efficiency heat transfer threaded flue gas tube is used to enhance heat transfer, and the boiler temperature and pressure rise are faster;At the same time, the flue gas has the function of high-speed disturbance in the pipe, so it is not easy to accumulate dust in the pipe, which plays the role of self-cleaning.

5.There is secondary air on both sides of the boiler wall, which can effectively organize the mixing of volatile matter and empty point in the fuel, promote the full combustion of volatile matter in the furnace, and improve the efficiency of fuel burnout.

6.The boiler adopts the anti coking header structure, which is located on both sides of the grate and directly contacts with the burning material layer, becoming the main heat absorbing surface at the bottom of the furnace.The purpose is to absorb part of the heat, adjust the temperature of the fuel layer, prevent coking, and cool the coking slag without bonding with the side wall.

7. A water-cooling device is arranged at the valve of the coal room of the boiler to reduce the temperature here and continue the precipitation rate of volatile matter, so that the boiler combustion is more stable and effectively alleviate the problem of "back burning" of biomass boiler.

8. Compact structure, compared with the same type of boiler, the overall size is small, saving the capital construction investment of boiler room.

9. Stable operation, convenient adjustment and sufficient output.It has certain overload capacity.

10. High efficiency and energy-saving furnace arch with integral pouring of heat-resistant and wet concrete is adopted in the furnace to improve fuel ignition conditions. Independent air chamber is adopted to achieve reasonable air distribution, forming an aerodynamic field conducive to combustion in the furnace, thus expanding the adaptability of fuel.

11. The arch and outlet window of the boiler have a certain dust removal effect.

Technical parameters: