1880 thermal paper coater, adopts several coating functions, coating for the production of special paper and other coating products.

call the hotline to learn more

.png) +86-18103825939

+86-18103825939

.png) +86-18103825939

+86-18103825939

1880 thermal paper coater, which is made by introducing foreign exquisite coating machine technology and its own experience in producing coater for many years, adopts several coating functions, coating for the production of special paper and other coating products.

The technological process of 1880 thermal paper coater is as follows:

Automatic unwinding of base material -- coating unit -- drying unit -- traction unit -- automatic winder

The performance and characteristics of 1880 thermosensitive paper coater:

1. the whole machine is controlled by 5 frequency conversion motor, and the whole machine tension is controlled automatically by PLC frequency conversion system. The stability of the tension of the whole machine is very high through the touch screen control and display of human-machine interface.

2. the paper releasing part is automatic paper receiving with electric turning double station, and the tension control of dancing roller is adopted.

3. the coating method of back roller scraper is first fed by the belt roller, and then quantitatively scraped by the scraper back roll.

4. the back roller air knife coating method is first fed by the belt roller, and then quantitatively coated by the air knife back roll.

5. the oven is 4.5m, with 6 independent frequency conversion and temperature control. The heating adopts natural gas direct combustion hot air heating, hot air enters the drying system, and can be adjusted internal circulation suction and exhaust device. The wind force of inlet and exhaust is strong, the wind force is even and controllable, and the drying is complete.

6. the guide wheel in the oven is synchronized with the main machine actively, and the synchronous belt wheel transmission and net dragging type are adopted for transmission, which can reduce the material stretching and deformation. The cylinder open top oven and the paper piercing operation platform make the operator easy to work.

7. the tension is controlled by PLC automatically by synchronous floating swing arm.

8. the PLC automatic meter speed control device.

9. EPC ultrasonic edge machine is used for rectifying deviation, so as to keep the materials in order to be rolled.

10. Key type air expanding shaft is used for retraction and release, which is convenient for loading and unloading.

11. the winding part is in the form of central curling and automatic paper connection.

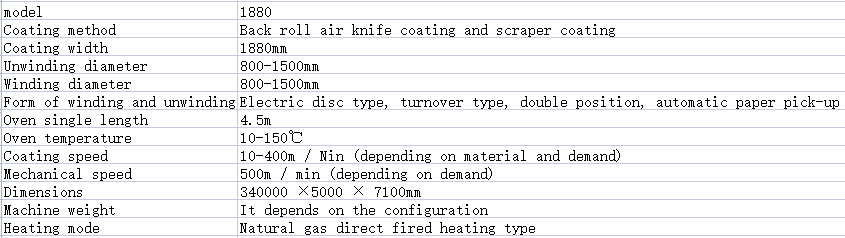

Technical parameters of 1880 thermal paper coater: