The impurity separator is used together with the sediment well to remove a large amount of light and a small amount of heavy matter from the pulper in the waste paper treatment process of pulp and paper industry.

call the hotline to learn more

.png) +86-18103825939

+86-18103825939

.png) +86-18103825939

+86-18103825939

The impurity separator is used together with the sediment well to remove a large amount of light and a small amount of heavy matter from the pulper in the waste paper treatment process of pulp and paper industry.

This series of products in the sediment well, in the pulping process of the pulper, the slurry containing coarse and heavy impurities gathered in the sediment well, overflow into the impurity separator, under the action of its rotor, the good pulp through the sieve plate into the next process. The coarse impurities are retained in the impurity separator and discharged after being washed regularly and sent to the cylinder screen for dehydration. The equipment can remove the impurities in the waste paper pulp as soon as possible, avoid refining the impurities in the process of crushing, reduce the load of the equipment in the next process, and improve the production capacity of the pulper. The machine is a supporting equipment in the continuous pulping system, with the advantages of high impurity removal efficiency, large production capacity, compact structure, convenient installation and maintenance, etc.

Structure principle of impurity separator:

The equipment is mainly composed of front cover, casing, rotor device, base, transmission device, etc.

1. A slurry inlet pipe and a heavy slag discharge pipe are arranged on the front cover.

2. The light slag discharge pipe is set in the front of the casing, the flange at the end is connected with the slurry plate in the rotor device, and the connecting bottom plate on both sides is connected with the base.

3. The rotor device is mainly composed of rotor, auxiliary shaft, slurry tray, sieve plate device, bearing seat, transmission support, large triangle pulley, etc. The rotor is made of wear-resistant cast steel. There are adjusting bolts on the rotor device, which can adjust the clearance between the sieve plate and the rotor.

4. The base is used to support the casing and transmission part.

5. The transmission device is mainly composed of motor, small V-belt pulley, motor bracket and V-belt.

Advantages of impurity separator:

1. The specially designed rotor can effectively avoid the fragmentation and refinement of impurities.

2. Impurities can be discharged according to different specific gravity.

3. Remove the impurities in the pulp as soon as possible to reduce the burden of pulper and subsequent process equipment.

4. It is equipped with automatic control system to make the slag discharge process convenient and reliable.

5. Openable front cover design makes maintenance more convenient.

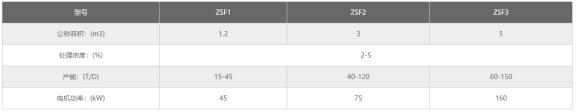

Technical parameters of impurity separator: