The high consistency slag remover is an ideal equipment to remove heavy impurities such as metal and sand in the pulp at high consistency, so as to obtain high quality pulp.

call the hotline to learn more

.png) +86-18103825939

+86-18103825939

.png) +86-18103825939

+86-18103825939

The high consistency slag remover is an ideal equipment to remove heavy impurities such as metal and sand in the pulp at high consistency, so as to obtain high quality pulp. It is also a necessary equipment for waste paper pulping purification.

Structure principle of high concentration slag remover:

1.High concentration slag remover (volute type)

The machine is composed of feeding tee, slurry outlet pipe, large cone, shell, sediment tank, etc.The upper part of the cone is made of wear-resistant cast iron and the tail part is made of glass, with smooth interior and long service life.The slurry enters from the upper feed tee tangent line, and the good slurry outlet is in the middle of the upper part.The lower cone part is provided with a balance water inlet, the bottom part is provided with a gate valve and a sediment tank, and the lower cone part and the sediment tank are respectively provided with a sight glass.

The equipment has a reasonable design of the upper feed tee and the slurry outlet pipe, the separation cone is long, and a good separation and slag removal effect can be obtained under the condition of high slurry concentration.

The high concentration slag remover uses the different proportion of fiber and impurities to separate impurities.The slurry enters the deslagging device at a certain pressure from the feed tee tangent line and then rotates at a high speed. Due to the different centrifugal force, the heavy impurities are thrown to the wall of the deslagging device. Under the action of gravity, they gradually move to the bottom of the cone and enter the sediment tank.Due to the small centrifugal force, the fiber gradually moves to the low pressure area in the center, and after reaching the bottom, the vortex rises, and finally it is discharged from the good pulp outlet.The cone of the high consistency slag remover has a certain taper, and the cone is longer. The rotation radius of the pulp in the cone is gradually reduced, so as to avoid the reduction of the speed of the pulp flow in the rotation process, ensure the centrifugal force to be strengthened, and improve the purification efficiency of the paper.The balance water pressure at the bottom is slightly greater than the slurry pressure, so that the fiber can not enter the sediment tank, only heavy impurities such as sand, metal particles, rubber blocks and plastics sink into the tank, reducing the loss of f

2. HD type high concentration slag remover

The machine is composed of feeding tee, cone, frame and sediment tank.The cone is lined with wear-resistant ceramics and the tail is made of glass, which has smooth interior and long service life.The slurry enters from the upper feed tee tangent line, and the good slurry outlet is in the middle of the upper part.The lower cone is provided with a balance water inlet, the bottom is provided with a gate valve and a sediment tank, and the sediment tank is provided with a sight glass.

The equipment has a reasonable design of the upper feed tee and the slurry outlet pipe, the separation cone is long, and a good separation and slag removal effect can be obtained under the condition of high slurry concentration.

The high concentration slag remover uses the different proportion of fiber and impurities to separate impurities.The slurry enters the deslagging device at a certain pressure from the feed tee tangent line and then rotates at a high speed. Due to the different centrifugal force, the heavy impurities are thrown to the wall of the deslagging device. Under the action of gravity, they gradually move to the bottom of the cone and enter the sediment tank.Due to the small centrifugal force, the fiber gradually moves to the low pressure area in the center, and after reaching the bottom, the vortex rises, and finally it is discharged from the good pulp outlet.The cone of the high consistency slag remover has a certain taper, and the cone is longer. The rotation radius of the pulp in the cone is gradually reduced, so as to avoid the reduction of the speed of the pulp flow in the rotation process, ensure the centrifugal force to be strengthened, and improve the purification efficiency of the paper.The balance water pressure at the bottom is slightly greater than the slurry pressure, so that the fiber can not enter the sediment tank, only heavy impurities such as sand, metal particles, rubber blocks and plastics sink into the tank, reducing the loss of fiber.

Advantages of high concentration slag remover:

1.Large observation window, easy to operate and control;

2.The separation cone is long, the cone angle is small, and the slag removal efficiency is high;

3.The cone is made of wear-resistant ceramic material with long service life;

4.Special quick opening slag discharge control valve, full slag discharge and easy operation.

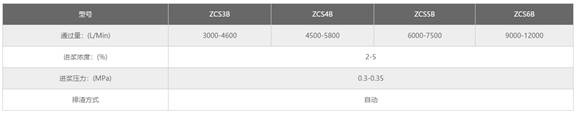

Technical parameters of high concentration slag remover (volute type)

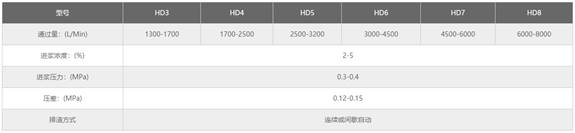

Technical parameters of HD High Concentration slag remover: